Introduction:

North America 4 Inches Semi-Insulating Silicon Carbide Wafer Market Size is expected to grow USD 0.17435 Billion by 2032, at (CAGR) of 12.30% during the forecast period (2023 - 2032).

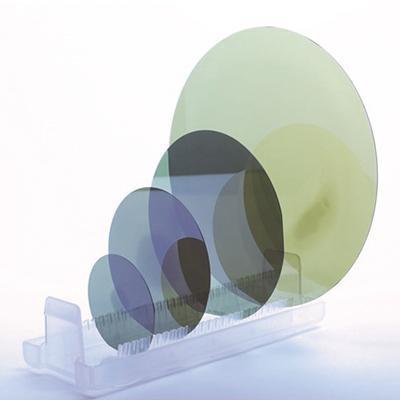

Silicon carbide (SiC) wafers have emerged as a crucial component in various semiconductor applications, offering superior performance and efficiency compared to traditional silicon wafers. Among these, 4-inch semi-insulating silicon carbide wafers hold significant importance in the North American market due to their wide-ranging applications in power electronics, telecommunications, aerospace, and automotive industries. This article provides an in-depth analysis of the North America market for 4-inch semi-insulating silicon carbide wafers, exploring key trends, drivers, challenges, and growth opportunities.

Analysis of 4-Inch Semi-Insulating Silicon Carbide Wafers Market:

4-inch semi-insulating silicon carbide wafers are substrates used for the fabrication of high-performance semiconductor devices such as power MOSFETs, Schottky diodes, and RF devices. These wafers are characterized by their semi-insulating properties, which prevent unwanted electrical conduction and enable the development of high-frequency, high-power devices with minimal interference.

Key Market Drivers:

- Rising Demand for Power Electronics: The increasing demand for power electronics in applications such as electric vehicles, renewable energy systems, and industrial automation is driving the need for high-performance semiconductor materials like silicon carbide wafers.

- Growing Adoption of Wide Bandgap Semiconductors: Silicon carbide is considered a wide bandgap semiconductor with superior thermal conductivity and breakdown voltage, making it ideal for high-power, high-temperature applications. As industries increasingly shift towards wide bandgap materials, the demand for 4-inch semi-insulating silicon carbide wafers is expected to surge.

- Advancements in Semiconductor Manufacturing: Ongoing advancements in semiconductor manufacturing processes, such as epitaxial growth, wafer bonding, and substrate engineering, are enabling the production of high-quality 4-inch semi-insulating silicon carbide wafers with improved performance characteristics.

- Government Initiatives and Investments: Government initiatives aimed at promoting clean energy technologies, enhancing energy efficiency, and reducing greenhouse gas emissions are driving investments in the development and commercialization of silicon carbide-based semiconductor devices, thereby boosting the demand for 4-inch semi-insulating silicon carbide wafers.

Market Challenges:

- High Manufacturing Costs: The manufacturing of 4-inch semi-insulating silicon carbide wafers involves complex processes and requires specialized equipment, leading to relatively high production costs compared to other semiconductor materials.

- Limited Availability of Substrates: The availability of high-quality silicon carbide substrates for wafer fabrication remains limited, posing a challenge for manufacturers to scale up production and meet growing demand.

- Technological Barriers: Despite significant advancements, there are still technological barriers to overcome in terms of wafer quality, uniformity, and defect density, which may hinder the widespread adoption of 4-inch semi-insulating silicon carbide wafers.

Get a free sample @ https://www.marketresearchfuture.com/sample_request/16159

Key Companies in the 4 Inches Semi-Insulating Silicon Carbide Wafer market include:

- Wolfspeed

- SK Siltron

- Showa Denko

- Norstel

- SiCrystal

- TankeBlue

- SICC

- II-VI Advanced Materials

- Hebei Synlight Crystal

Future Outlook:

The North America market for 4-inch semi-insulating silicon carbide wafers is poised for robust growth, driven by increasing investments in research and development, expanding applications in power electronics and telecommunications, and the growing emphasis on energy efficiency and sustainability. Manufacturers are expected to focus on improving production processes, enhancing wafer quality, and expanding substrate availability to capitalize on emerging opportunities in the semiconductor industry. Overall, 4-inch semi-insulating silicon carbide wafers are set to play a crucial role in advancing next-generation semiconductor technologies and enabling the transition towards a greener and more sustainable future.

Read more article -

Industrial Semiconductors Market Research Report – Forecast till 2032

Photonics Market Research Report – Forecast till 2032

Visible Light Communication Li-Fi Market Research Report – Forecast till 2032

Wi-Fi Booster Market Research Report – Forecast till 2032

Intelligent Platform Management Interface Market Research Report – Forecast till 2032