Market Research Future Insights

The Ball Valves market industry is projected to grow from USD 13.00 billion in 2022 to USD 18.07 billion by 2030, exhibiting a compound annual growth rate (CAGR) of 4.2% during the forecast period (2022 - 2030). Market Research Future has recently published a report on the market, highlighting various trends and factors driving its growth.

The report suggests that the increasing demand for ball valves in various industries, such as oil and gas, chemicals, and water and wastewater treatment, is a major factor propelling the market's growth. Additionally, the growing trend of automation in industrial processes is also expected to drive the market's expansion.

"Request Free Sample" - https://www.marketresearchfuture.com/sample_request/3349

Industry Trends

The ball valves market is witnessing several trends that are expected to shape the market in the coming years. One major trend is the increasing adoption of automation in industrial processes. The use of automated ball valves offers several benefits, such as improved efficiency, reduced downtime, and increased safety.

Another trend is the growing demand for cryogenic ball valves. Cryogenic ball valves are designed to withstand extremely low temperatures and are commonly used in industries such as healthcare, aerospace, and food and beverage.

Key Players

- Emerson Electric Co.

- Flowserve Corporation

- Cameron International Corporation

- Kitz Corporation

- Crane Co.

- IMI plc

- Metso Corporation

- Neway Valve Co., Ltd.

- Velan Inc.

- Weir Group plc

Introduction:

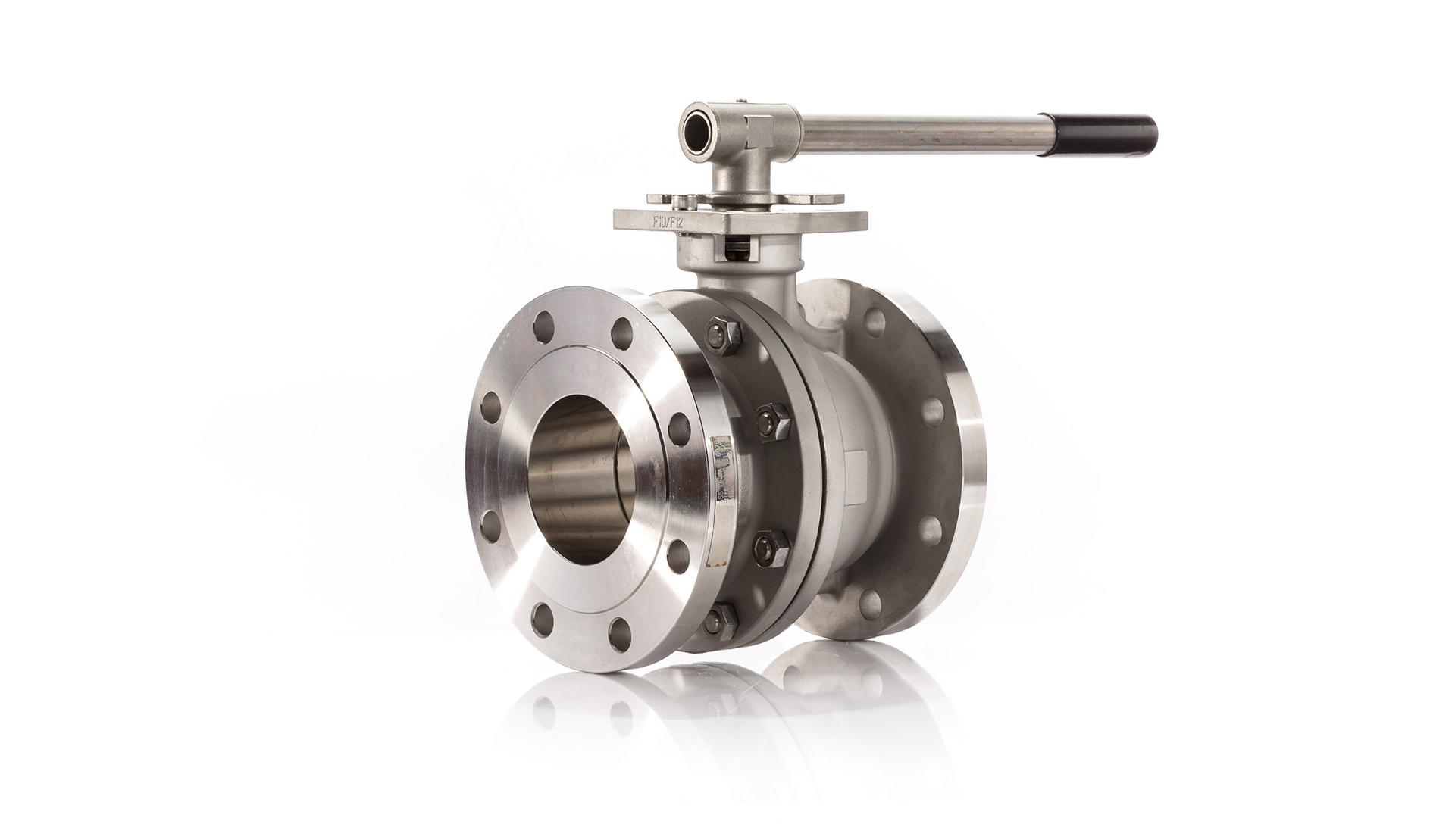

In today's dynamic industrial landscape, maintaining a seamless flow of fluids and gases is vital for numerous sectors, ranging from oil and gas to pharmaceuticals and manufacturing. Among the essential components ensuring efficient fluid control are ball valves. These mechanical marvels have become indispensable in the industry due to their reliability, versatility, and durability. This blog post will delve into the thriving ball valves industry, exploring its current state, trends, and future prospects.

Key Factors Driving the Growth:

- Expanding Industrial Applications: The versatility of ball valves allows them to cater to a wide range of industries. From oil and gas exploration to water treatment plants, chemical processing, power generation, and more, ball valves find applications in critical processes that require precise control and shut-off functions.

- Technological Advancements: Continuous innovation and technological advancements have played a pivotal role in the growth of the ball valves industry. Manufacturers are developing advanced ball valve designs, such as trunnion-mounted, floating, and top-entry ball valves, to meet the evolving demands of different industries.

- Increasing Focus on Safety: Safety concerns have led industries to adopt reliable valve systems to ensure the secure and efficient handling of fluids and gases. Ball valves, with their tight sealing capabilities and low leakage rates, provide enhanced safety measures, making them the valve of choice for critical operations.

- Growing Investments in Infrastructure: The rise in infrastructure development projects, particularly in emerging economies, has bolstered the demand for ball valves. These valves are vital components in various infrastructure projects, including pipelines, refineries, and power plants, contributing to the industry's growth.

- Environmental Regulations: The stringent environmental regulations imposed by governments worldwide have led to increased adoption of ball valves due to their superior environmental performance. The ability of ball valves to prevent leaks and reduce fugitive emissions aligns with sustainability goals, making them an attractive choice for environmentally conscious industries.

Emerging Trends in the Ball Valves Industry:

- Smart and Connected Valves: With the advent of the Industrial Internet of Things (IIoT), smart and connected ball valves are gaining traction. These valves are equipped with sensors and actuators that enable remote monitoring, control, and predictive maintenance, improving operational efficiency and reducing downtime.

- Integration of Automation: Automation technologies, such as programmable logic controllers (PLCs) and distributed control systems (DCS), are being integrated with ball valves to enhance process control and optimize overall system performance. This integration enables seamless integration with other equipment and improves productivity.

- Focus on Material Innovation: Manufacturers are investing in research and development to explore innovative materials for ball valve construction. The goal is to improve durability, corrosion resistance, and reliability, while also addressing specific industry needs, such as high temperatures or corrosive environments.

- Energy-Efficient Solutions: Energy efficiency is a key concern for industries aiming to reduce operational costs and minimize their carbon footprint. The ball valves industry is responding by developing energy-efficient designs that minimize pressure drop, resulting in significant energy savings over the valve's lifespan.

Related Reports:

Conclusion:

The ball valves industry is experiencing remarkable growth due to its indispensable role in fluid control across various industries. With continuous technological advancements, increasing safety requirements, and a focus on sustainability, ball valves are revolutionizing the industrial landscape. The industry's bright future is further fueled by emerging trends such as smart and connected valves, automation integration, material innovation, and energy-efficient solutions. As the demand for efficient fluid control continues to surge, the ball valves industry stands ready to meet the needs of a rapidly evolving industrial world.